The foundation of exceptional chocolate products lies in the quality of ingredients you source. Whether you're launching a boutique chocolate shop, an artisanal confectionery, or scaling an existing chocolate business, your ingredient choices will directly impact flavor profiles, product consistency, brand reputation, and ultimately, your bottom line. This guide explores the intricate world of chocolate ingredient sourcing, helping you navigate relationships with suppliers, understand quality indicators, and make sustainable choices that align with modern consumer values.

Understanding Cacao Sourcing: The Heart of Chocolate

The Geography of Flavor

Cacao beans, like wine grapes, express terroir—the environmental factors that affect a crop's phenotype. Beans from different regions offer distinct flavor profiles:

-

West African beans (Ghana, Côte d'Ivoire) typically provide consistent, mild chocolate notes with subtle earthiness—ideal for mainstream products requiring reliability.

-

South American varieties (Venezuela, Ecuador, Peru) often deliver complex flavor profiles with floral, fruity, and nutty notes—perfect for premium single-origin offerings.

-

Southeast Asian beans (Vietnam, Indonesia) frequently present robust, sometimes smoky characteristics with spicy undertones—excellent for creating distinctive blends.

-

Caribbean cacao (Dominican Republic, Trinidad) tends to offer bright, fruity profiles with wine-like acidity—suitable for craft chocolates targeting connoisseurs.

Understanding these regional differences allows you to select beans that align with your product vision and target consumer preferences.

Zucchero Canada specializes in premium Venezuelan and Peruvian cocoa beans, which are renowned for their complex flavor profiles. Their high-quality beans provide chocolatiers with an excellent foundation for creating distinctive chocolates that capture the unique terroir of these regions.

Direct Trade vs. Traditional Supply Chains

Modern chocolate businesses have multiple sourcing options:

Direct Trade Relationships involve working directly with farms or cooperatives, offering:

-

Greater transparency and quality control

-

Potentially higher-quality beans through collaborative improvement

-

Premium storytelling opportunities for marketing

-

More equitable pricing for farmers

-

Challenges in logistics, consistent volume, and relationship management

Importers and Brokers provide:

-

Convenience and reliability in supply

-

Quality verification services

-

Simplified logistics

-

Potentially higher costs due to intermediaries

-

Less direct connection to the source

The best approach often combines both methods, depending on your scale, resources, and brand values.

Quality Indicators for Cacao

When evaluating cacao suppliers, consider these quality factors:

-

Bean size and uniformity: Consistent bean size indicates careful sorting and processing

-

Fermentation level: Properly fermented beans (indicated by brown interior rather than purple) develop complex flavors

-

Moisture content: Ideally between 6-7%; higher levels risk mold growth

-

Defect rate: Premium cacao should have minimal defects (flat beans, insect damage, mold)

-

Cut test results: Assessment of internal bean characteristics revealing fermentation quality

-

Flavor profile: Sensory evaluation should align with your chocolate recipe expectations

Requesting samples for evaluation before committing to large orders allows you to assess these qualities directly.

Beyond Cacao: Other Essential Ingredients

Sugar Selection

Sugar does more than sweeten—it affects texture, preservation, and flavor complexity:

-

Refined white sugar: Neutral sweetness that doesn't compete with cacao flavors

-

Raw cane sugar: Adds subtle molasses notes complementing earthy chocolate tones

-

Coconut sugar: Lower glycemic option with caramel-like profile

-

Alternative sweeteners: Maple sugar, date sugar, or monk fruit for specialty dietary products

The particle size of sugar also matters—finer granulation creates smoother chocolate while larger crystals can provide texture in certain applications.

Dairy Considerations

For milk chocolate and white chocolate products:

-

Milk powder options: Whole milk powder creates richer mouthfeel than skim milk powder

-

Cream powder: Offers luxurious texture but accelerates oxidation

-

Specialty dairy: Goat's milk powder or sheep's milk powder provides distinctive flavor profiles

-

Plant-based alternatives: Coconut milk powder, oat milk powder, or soy milk powder for vegan offerings

Selecting dairy ingredients with consistent fat content ensures product stability across batches.

Additional Flavor Enhancement

-

Vanilla: Madagascar bourbon vanilla offers classic, rich profiles while Tahitian vanilla provides floral notes

-

Salt: Fleur de sel, Himalayan pink salt, or smoked salts can elevate flavor complexity

-

Spices: Cinnamon, cardamom, chili, or other spices should be freshly ground for optimal potency

-

Emulsifiers: Lecithin (soy or sunflower) improves texture and processing characteristics

Professional Equipment and Tools

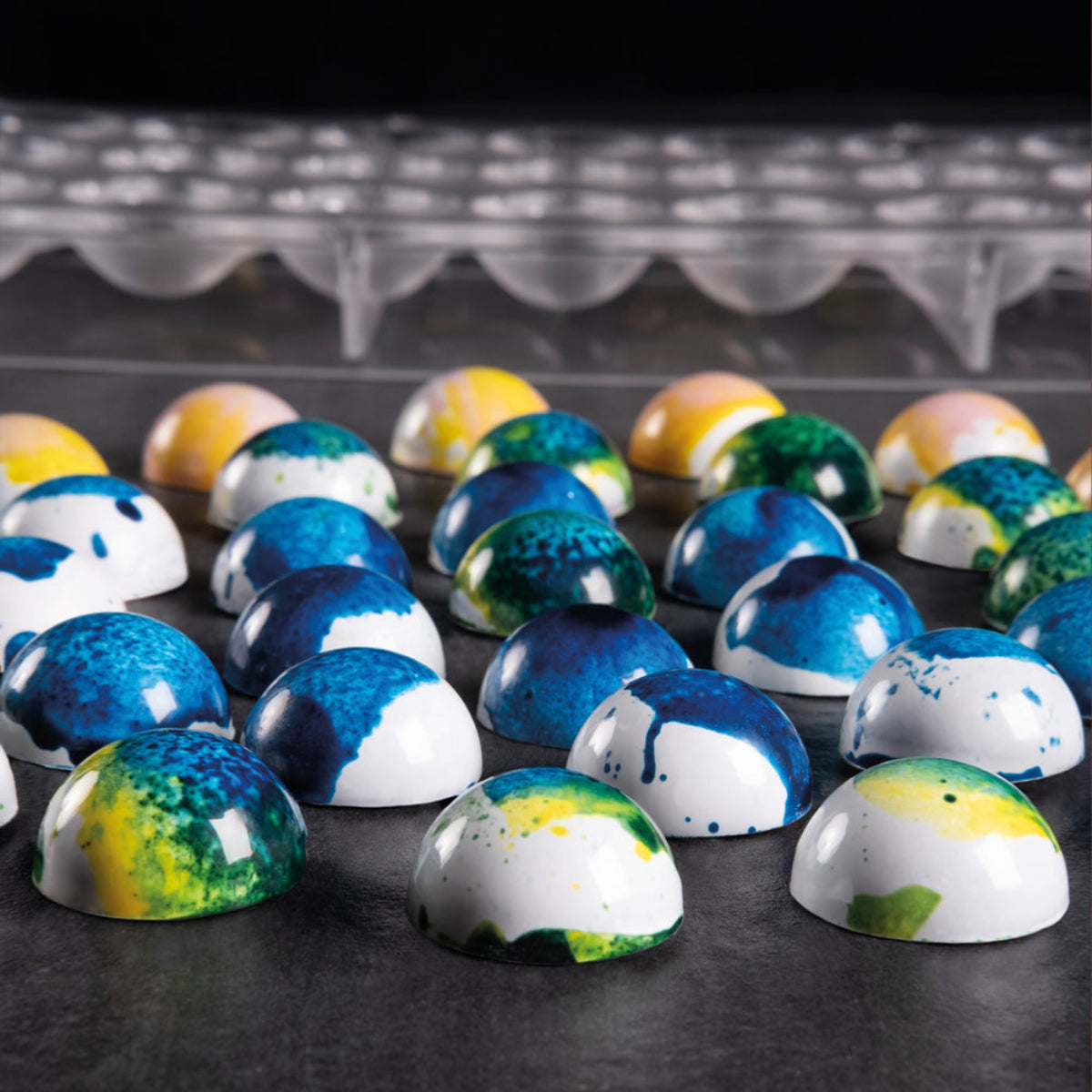

Having the right tools is just as important as quality ingredients. For professional chocolatiers and passionate home bakers alike,at Zucchero Canada weoffers specialized chocolate molds and baking tools designed to help you create visually stunning and perfectly textured chocolates.

Our selection of professional-grade equipment complements their premium cocoa beans, allowing you to maximize the potential of your ingredients.

Building Supplier Relationships

Vetting Process

Develop a systematic approach to evaluating potential suppliers:

-

Request samples and specifications: Assess ingredient quality directly

-

Verify certifications: Organic, Fair Trade, Rainforest Alliance, or other relevant standards

-

Audit facilities: Either personally or through third-party verification

-

Check references: Contact other businesses using their ingredients

-

Assess communication responsiveness: Good suppliers respond promptly to inquiries

-

Evaluate logistical capabilities: Reliable delivery schedules and contingency plans

-

Price transparency: Clear understanding of pricing structures and fluctuations

Negotiating Terms

When establishing supplier agreements, consider:

-

Minimum order quantities: Ensure they align with your production scale

-

Payment terms: Net-30 or longer terms can help cash flow management

-

Exclusivity options: Some suppliers offer unique ingredients for exclusive use

-

Shipping arrangements: FOB (Free On Board) vs. delivered pricing affects your logistics

-

Quality guarantees: Specifications, testing protocols, and remediation procedures

-

Sustainability commitments: Documented environmental and social practices

Risk Management

Diversify your supply chain to mitigate risks:

-

Multiple suppliers: Maintain relationships with backup suppliers for critical ingredients

-

Buffer inventory: Maintain adequate stock to weather supply disruptions

-

Futures contracts: For larger operations, consider hedging against price volatility

-

Seasonal planning: Anticipate harvest cycles and potential quality variations

Quality Control Systems

Incoming Ingredient Assessment

Implement consistent protocols for evaluating ingredients upon receipt:

-

Visual inspection: Check for obvious defects or contamination

-

Sensory evaluation: Taste, smell, and texture assessment

-

Moisture analysis: Critical for cacao beans and powdered ingredients

-

Microbiological testing: Particularly important for raw ingredients

-

Storage transfer: Proper temperature and humidity-controlled environments

Documentation and Traceability

Maintain comprehensive records:

-

Lot tracking: System to trace ingredients through production

-

Certificate of Analysis (COA): Documentation of supplier testing

-

Internal quality reports: Your assessment results

-

Shelf-life monitoring: Tracking ingredient freshness

Sustainability and Ethical Considerations

Environmental Impact

Consider these environmental factors when selecting suppliers:

-

Cultivation practices: Agroforestry vs. monoculture impacts on biodiversity

-

Processing methods: Water and energy usage efficiency

-

Packaging materials: Recyclable or compostable options

-

Transportation footprint: Local sourcing vs. international shipping impacts

Social Responsibility

Evaluate the human element of your supply chain:

-

Labor practices: Fair wages and safe working conditions

-

Community investment: Educational programs, healthcare access, infrastructure development

-

Indigenous rights: Respect for traditional knowledge and land rights

-

Gender equity: Women's empowerment initiatives in traditionally male-dominated industries

Certifications Worth Considering

While not mandatory, these certifications provide third-party verification:

-

Organic: Verifies absence of prohibited synthetic inputs

-

Fair Trade: Ensures minimum price guarantees to producers

-

Rainforest Alliance: Focuses on environmental conservation alongside social standards

-

Direct Trade: Company-specific verification of equitable trading practices

-

B Corp: Holistic assessment of social and environmental performance

Navigating Scaling Challenges

Small-Batch to Commercial Production

As your business grows, your sourcing strategy must evolve:

-

Maintaining quality at scale: Finding suppliers who can consistently meet larger volume needs

-

Ingredient standardization: Developing specifications that ensure consistency despite natural variations

-

Blending strategies: Creating proprietary blends that maintain flavor profiles despite seasonal variations

-

Vertical integration: Considering investment in processing facilities for greater control

Inventory Management Systems

Implement systems appropriate to your scale:

-

Just-in-time vs. safety stock: Finding the right balance for your operation

-

FIFO protocols: Ensuring proper ingredient rotation

-

Freshness monitoring: Tracking ingredient viability throughout shelf life

-

Seasonal purchasing: Aligning orders with harvest cycles for optimal quality

Conclusion

Sourcing high-quality ingredients for your chocolate business requires diligence, relationship building, and systems thinking. By understanding the nuances of cacao sourcing, implementing robust quality control, cultivating supplier relationships, and embracing sustainable practices, you position your chocolate business for long-term success. Remember that ingredient quality isn't merely about production values—it represents your brand's commitment to excellence, shapes your marketing narrative, and ultimately determines customer satisfaction and loyalty. As the specialty chocolate market continues to grow, businesses that demonstrate thoughtful ingredient sourcing will find themselves well-positioned to thrive in this increasingly discerning marketplace.

Dejar un comentario

Todos los comentarios se revisan antes de su publicación.

Este sitio está protegido por hCaptcha y se aplican la Política de privacidad de hCaptcha y los Términos del servicio.