Professional guidance on selecting the right chocolate processing equipment for your needs - featuring premium equipment from Zucchero Canada

Chocolate processing equipment represents a significant investment for any confectionery business. Understanding the fundamental differences between chocolate melters and temperers is essential for producing quality chocolate products efficiently. This comprehensive guide examines these specialized tools, with a focus on professional-grade equipment from industry leader

Chocolate Melter: Foundation of Chocolate Work

Core Functionality and Design

A chocolate melter is designed specifically to transform solid chocolate into liquid form at controlled temperatures. Unlike regular kitchen appliances, professional chocolate melters like the Mol d'Art 6kg Chocolate Melter provide precise temperature control essential for properly handling delicate chocolate formulations.

The basic components of a professional chocolate melter include:

- Thermally insulated melting tanks with non-stick surfaces

- Digital temperature controls with ±1-2°C precision

- Gentle, indirect heating elements to prevent scorching

- Removable tanks for easy cleaning

- Adjustable temperature ranges (typically 20-60°C)

Zucchero Canada's melters feature additional professional-grade elements such as stainless steel construction, seamless design for improved hygiene, and digital display systems for consistent operation.

Multi-Tank Melting Systems

For operations working with multiple chocolate varieties simultaneously, multi-tank systems like the MeltinChoc Multi-Tank 3L Melter provide exceptional versatility. These systems allow pastry chefs and chocolatiers to maintain different chocolate types (dark, milk, white) at their respective optimal temperatures.

Multi-tank systems offer several distinct advantages:

- Elimination of cross-contamination between chocolate types

- Independent temperature control for each tank

- Streamlined workflow for multi-component creations

- Reduced cleaning requirements during production runs

- More efficient use of counter space versus multiple single-tank units

Applications Ideally Suited for Melters

Chocolate melters excel in specific applications where maintaining liquid chocolate at working temperature is the primary requirement:

- Bakery Integration: Bakeries typically use melters for incorporating chocolate into recipes rather than creating finished chocolate pieces. The Mol d'Art 6kg model offers capacity ideal for medium-production bakeries.

- Compound Chocolate Work: When working with compound chocolate (cocoa with vegetable fats instead of cocoa butter), the crystallization control of a temperer becomes unnecessary, making melters the more cost-effective solution.

- Chocolate Sauce Production: Restaurants and cafés producing chocolate sauces, fondue, or dipping chocolate benefit from melters' ability to maintain liquid chocolate for extended periods.

- Manual Tempering Support: For artisanal operations practicing manual tempering techniques, a quality melter provides the base melted chocolate that becomes the foundation of the manual process.

Chocolate Temperer: Precision Engineering for Chocolate Crystallization

The Science of Tempering

Chocolate tempering requires precise thermal cycling to ensure cocoa butter forms the correct crystal structure (Type V beta crystals). This molecular orchestration is what gives properly tempered chocolate its shine, snap, and stability.

A professional chocolate temperer automates this complex process with specialized machinery:

- Programmed heating cycles to precise temperatures

- Cooling systems to promote proper crystallization

- Continuous agitation to develop uniform crystal structure

- Precision temperature control (often within ±0.1°C)

- Baffle systems to incorporate seed crystals throughout the mass

Professional-Grade Tempering Equipment

Zucchero Canada's tempering machines collection features equipment engineered specifically for professional chocolate production. These machines represent significant technological advancement over basic melters:

- Continuous Cycle Systems: Maintain chocolate in perfect temper indefinitely during production

- Programmable Memory: Store specific programs for different chocolate formulations

- Vibration Tables: Integrated or complementary equipment to remove air bubbles

- Automated Seed Management: Precise introduction of seed chocolate for crystal formation

- Production-Scale Capacity: Ranging from small artisanal (5kg) to industrial production (150kg+)

Applications Requiring Temperers

Professional-grade tempering machines become essential for operations focused on:

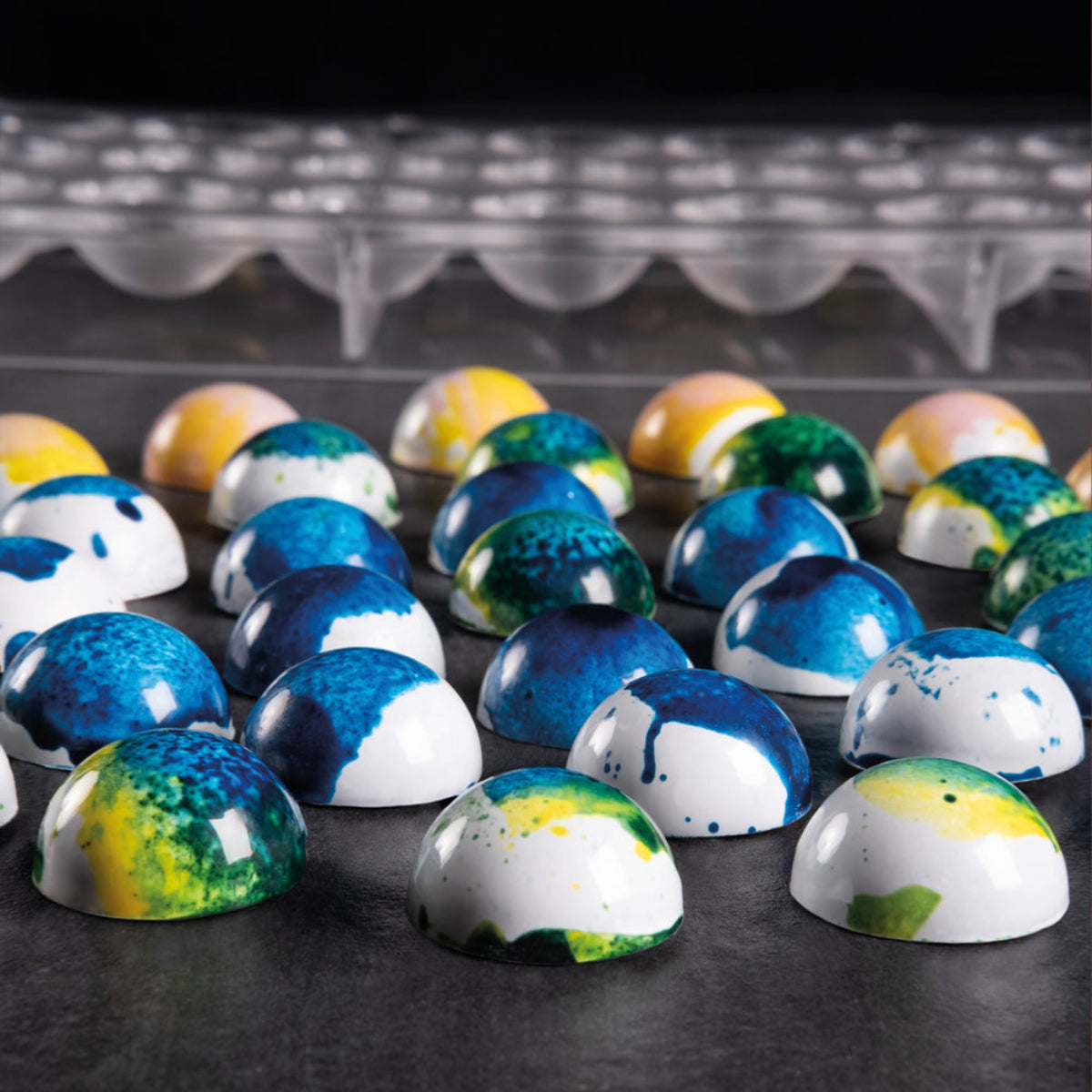

- Bonbon and Praline Production: Filled chocolates require perfectly tempered shells for appearance and shelf stability

- Chocolate Bar Manufacturing: Consumer-ready chocolate bars depend on proper crystallization for quality, appearance, and handling properties

- High-Volume Operations: When production quantity makes manual tempering impractical

- Premium Confectionery Brands: Where consistency and quality are paramount to brand reputation

- Chocolate Showpieces: Artistic chocolate work demands perfectly tempered chocolate for structural integrity

Direct Comparison: Performance Analysis

Temperature Control Precision

Melters: Equipment like the Mol d'Art Chocolate Melter provides temperature control typically within ±1-2°C. This precision is adequate for maintaining melted chocolate but insufficient for controlling crystal formation.

Temperers: Professional tempering machines from Zucchero Canada's collection offer precision within ±0.1°C through multi-zone heating/cooling systems. This level of precision is critical for proper crystal development.

Production Efficiency

Melters: Require additional manual steps to achieve tempered chocolate, creating potential bottlenecks. A standard melter like the Mol d'Art 6kg model requires operator attention for tempering.

Temperers: Provide start-to-finish processing with minimal operator intervention. Once programmed, tempering machines can maintain chocolate in perfect working condition throughout production shifts.

Consistency of Results

Melters: Results depend heavily on operator skill when used for tempered chocolate applications. Even experienced chocolatiers face variables that affect consistency when working with melters alone.

Temperers: Produce remarkably consistent results regardless of ambient conditions or operator variables. This consistency translates directly to product quality and reduced waste.

Technical Specifications Comparison Table

| Specification | Mol d'Art 6kg Melter | Professional Temperer |

|---|---|---|

| Temperature Range | 20-60°C | 20-60°C with precise cycling |

| Temperature Precision | ±1-2°C | ±0.1°C |

| Capacity | 6kg | 5-150kg (model dependent) |

| Agitation | Optional manual | Continuous programmed |

| Cooling System | None | Integrated |

| Crystal Management | None | Automated |

| Production Rate | Dependent on manual processing | 5-50kg/hour (model dependent) |

| Energy Consumption | Lower (200-400W) | Higher (500-2000W) |

Business Implementation Considerations

Space and Facility Requirements

Melters: Compact units like the MeltinChoc Multi-Tank system occupy minimal counter space. No special electrical requirements beyond standard outlets.

Temperers: Require dedicated workspace with proper clearance and often dedicated electrical circuits. Larger models need consideration for floor loading, ventilation, and workflow integration.

Staffing and Training Impact

Melters: Require staff skilled in manual tempering techniques when used for finished chocolate products. Training focuses on traditional chocolate handling methods.

Temperers: Reduce dependency on highly-skilled staff for consistent results. Training shifts to machine operation and maintenance rather than manual tempering techniques.

Maintenance Requirements and Lifecycle Costs

Melters: Simple construction with minimal moving parts results in lower maintenance costs. Units like the Mol d'Art Chocolate Melter offer excellent durability with proper care.

Temperers: More complex systems require regular professional maintenance and occasional recalibration. Higher initial investment but potentially lower labor costs over time.

Production Scale and Equipment Selection

Startup and Artisanal Operations

For businesses producing under 5kg of finished chocolate products daily, a strategic approach often involves:

- Beginning with a quality melter like the Mol d'Art 6kg model

- Developing manual tempering skills

- Reinvesting profits into a small professional temperer as production scales

This progressive approach allows new businesses to build skills while managing cash flow effectively.

Medium Production Operations

Operations producing 5-25kg of finished chocolate daily typically require:

- Multiple melting units or multi-tank systems like the MeltinChoc Multi-Tank

- At least one small professional tempering machine

- Workflow optimization between different equipment types

Zucchero Canada offers consultation services to help medium-scale producers optimize their equipment selection and configuration.

Large-Scale Production

High-volume operations producing over 25kg daily require comprehensive equipment strategies:

- Industrial-grade tempering systems with continuous flow capabilities

- Multiple melting stations for different production lines

- Integrated systems linking tempering with molding/enrobing equipment

- Automated cleaning systems for production efficiency

Hybrid Approaches and Workflow Integration

Strategic Equipment Combinations

Many professional chocolate operations maintain both melters and temperers to maximize production flexibility:

- Using melters for specific applications where tempering isn't required

- Leveraging tempering machines for finished chocolate products

- Creating efficient workflows where each equipment type handles appropriate tasks

Seasonal Production Considerations

Businesses with seasonal demand fluctuations can implement flexible strategies:

- Relying primarily on versatile melters like the Mol d'Art 6kg model during slower periods

- Adding tempering machine capacity during high-demand seasons

- Using equipment rental options for peak production periods

Complementary Equipment Integration

For complete chocolate production systems, Zucchero Canada provides complementary equipment that integrates with both melters and temperers:

- Chocolate molds and accessories

- Vibration tables for bubble removal

- Cooling tunnels and chambers

- Specialized chocolate tools and workspace equipment

Return on Investment Analysis

Calculating Equipment ROI

When evaluating chocolate processing equipment, consider these ROI factors:

- Production Efficiency: Temperers typically reduce production time by 30-60% compared to manual methods with melters

- Labor Costs: Automated tempering reduces skilled labor requirements by up to 70%

- Product Quality: Consistent tempering leads to lower rejection rates and returns

- Energy Consumption: Modern equipment from Zucchero Canada incorporates energy-efficient designs

- Equipment Lifespan: Professional-grade equipment typically provides 7-15 years of service with proper maintenance

Case Study: Artisanal Chocolate Shop

A small chocolate shop producing 10kg of bonbons daily achieved:

- 40% reduction in production time after upgrading from a Mol d'Art Melter to a professional temperer

- 25% reduction in rejected products due to improved tempering consistency

- ROI achieved within 14 months despite higher initial investment

- Increased production capacity without additional staff

Future Trends in Chocolate Processing Equipment

Technological Innovations

The chocolate equipment industry continues to evolve with innovations such as:

- IoT Integration: Remote monitoring and control of tempering parameters

- AI-Enhanced Processing: Adaptive tempering programs that respond to ambient conditions

- Energy Efficiency Improvements: Reduced consumption while maintaining precision

- Smaller Footprint Professional Equipment: More compact designs without sacrificing capabilities

Sustainability Considerations

Modern chocolate processing equipment from manufacturers like Zucchero Canada increasingly incorporates sustainability features:

- Water recirculation systems for cooling

- Energy-efficient heating elements

- Recyclable components

- Reduced water usage in cleaning processes

- Extended equipment lifespan through modular design

Expert Guidance on Equipment Selection

Consulting with Specialists

Zucchero Canada provides specialized consultation services to help businesses select the optimal equipment configuration. Their expertise includes:

- Production workflow analysis

- Space utilization planning

- Scaling strategies as businesses grow

- Integration of existing equipment with new acquisitions

- Technical training for staff

Equipment Demonstrations and Testing

Before making significant investments, consider:

- Requesting equipment demonstrations

- Participating in workshops using potential equipment

- Speaking with current users of similar systems

- Testing your specific chocolate formulations on demonstration equipment

Conclusion and Recommendations

The choice between chocolate melters and temperers depends on multiple factors specific to each operation. For many businesses, the optimal approach involves a strategic combination of equipment types like the Mol d'Art Melter for certain applications and professional tempering machines for others.

Zucchero Canada offers comprehensive equipment solutions ranging from accessible entry-level models to advanced professional systems. Their expertise in matching businesses with appropriate equipment ensures optimal investment in chocolate processing technology.

For personalized equipment recommendations based on your specific production needs, visit Zucchero Canada's tempering machines collection or contact their technical specialists for consultation services.

FAQ: Common Questions About Chocolate Processing Equipment

Can a chocolate melter be used to temper chocolate? A melter like the Mol d'Art 6kg model can be used as part of manual tempering processes but requires additional steps performed by a skilled operator to achieve proper crystallization.

Is it worth investing in a tempering machine for a small business? For operations producing more than 5kg of finished chocolate products daily, a tempering machine typically pays for itself within 12-24 months through labor savings and quality improvements.

What's the minimum equipment needed for a chocolate startup? Most successful chocolate startups begin with a quality melter such as those offered by Zucchero Canada and add tempering equipment as production scales.

How do multi-tank melters improve workflow? Systems like the MeltinChoc Multi-Tank allow simultaneous work with different chocolate types without cross-contamination, significantly improving production efficiency.

Can tempering machines handle white chocolate effectively? Yes, professional temperers can be programmed with specific temperature profiles for white chocolate, which requires lower temperatures than dark chocolate varieties.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.