Creating chocolate letters with molds transforms simple alphabet shapes into personalized confections perfect for celebrations, branding, educational gifts, and custom messaging. This comprehensive guide reveals expert methods for crafting bakery-quality chocolate letters using specialized molds, optimal tempering approaches, and creative decoration that elevates lettered chocolates from basic to impressive personalized treats.

Understanding Letter Mold Types and Applications

Chocolate letter production benefits from understanding various mold styles, each suited to different applications and skill levels.

Alphabet Mold Designs

Letter molds range from complete alphabet sets to individual character molds accommodating different production needs. The Letters and Numbers Polycarbonate Mould MA3005 provides comprehensive character set for projects, enabling complete word and message creation. Individual letter molds suit specialized applications requiring specific characters in larger quantities.

Font styles significantly impact chocolate letter appearance and readability. Block letters with substantial thickness release easily from molds and withstand handling better than delicate script fonts. Contemporary typography suits modern designs, while traditional serif fonts work for classic applications.

|

Mold Type |

Best Applications |

Advantages |

Skill Level |

|

Complete Alphabet Sets |

Full words, messages |

All characters available |

All levels |

|

Individual Letters |

Initials, high-volume single chars |

Large quantity production |

All levels |

|

3D Letter Molds |

Standing displays, centerpieces |

Dimensional impact |

Intermediate |

|

Script/Cursive |

Elegant gifts, weddings |

Sophisticated appearance |

Advanced |

Material Considerations

Polycarbonate molds deliver glossiest finish for chocolate letters, producing professional results with sharp detail reproduction. These rigid molds require proper tempering for clean release but reward careful technique with superior appearance. Silicone molds offer flexibility simplifying demolding, especially beneficial for delicate letter features like serifs or thin crossbars.

Consider letter size when selecting molds. Larger letters work well for cake toppers and standalone display pieces, while smaller letters suit bark incorporation, cupcake decoration, or scattered table arrangements. The cavity depth determines letter thickness; deeper cavities create substantial pieces while shallow cavities produce delicate decorative elements.

Essential Materials and Equipment

Chocolate Selection Strategies

Chocolate letters achieve optimal results with properly selected chocolate matching intended application. Couverture chocolate containing minimum 31% cocoa butter provides excellent flow properties capturing fine letter details. Dark Chocolate 55% Venezuela delivers rich flavor and professional performance, while FCH Milk Chocolate Latin American Origin 44% offers approachable taste.

White chocolate creates blank canvas for coloring, essential when matching brand colors or theme palettes. FCH White Chocolate Latin American Origin 28% accepts cocoa butter colors beautifully while maintaining structural integrity. For simplified production, White Chocolate Candy Melts 5kg eliminate tempering requirements.

Compound chocolate suits high-volume production where ease outweighs premium finish. These options melt smoothly without tempering, ideal for beginners learning letter production techniques.

Required Production Tools

Creating professional chocolate letters demands specific equipment beyond basic kitchen supplies. A digital thermometer ensures accurate temperature monitoring during tempering, while rigid plastic scrapers remove excess chocolate cleanly from mold surfaces without damaging cavities.

Professional melting equipment maintains consistent chocolate temperature throughout production sessions. The Chocolate Melter 3kg Capacity accommodates moderate batch sizes, while the Meltinchoc Multi-Tank 3L enables simultaneous work with multiple chocolate colors.

Additional supplies include parchment paper, small detail brushes for intricate work, and appropriate storage containers maintaining optimal conditions for finished chocolate letters.

Chocolate Tempering for Letter Molds

Proper tempering creates chocolate letters exhibiting professional snap, glossy finish, and resistance to bloom during storage and handling.

Tempering Temperature Guidelines

Successful letter molding requires precise temperature control throughout tempering process. The seeding method works reliably for letter production, introducing stable cocoa butter crystals throughout melted chocolate. Melt two-thirds chocolate to appropriate temperature based on variety, add remaining chocolate gradually while stirring, then gently reheat to working temperature.

|

Chocolate Type |

Melt Temperature |

Seed Temperature |

Working Temperature |

Letter Benefits |

|

Dark Chocolate |

115-120°F (46-49°C) |

82-84°F (28-29°C) |

88-90°F (31-32°C) |

Sharp edges, clean release |

|

Milk Chocolate |

110-115°F (43-46°C) |

82-84°F (28-29°C) |

86-88°F (30-31°C) |

Smooth finish, good detail |

|

White Chocolate |

105-110°F (40-43°C) |

80-82°F (27-28°C) |

82-84°F (28-29°C) |

Accepts colors well |

|

Ruby Chocolate |

105-110°F (40-43°C) |

80-82°F (27-28°C) |

82-84°F (28-29°C) |

Natural pink for letters |

Test temper by spreading small amount on parchment paper; properly tempered chocolate sets within 3-5 minutes developing slight matte finish that becomes glossy as crystallization completes. Professional tempering machines from our machines collection automate process eliminating guesswork from production.

Alternative Approaches for Beginners

Compound chocolate offers simplified approach eliminating tempering requirements entirely. Melt gently to 95-100°F (35-38°C), avoiding excessive heat damaging vegetable oils. Compound chocolate sets quickly producing letters ready for demolding within 20-30 minutes without complex temperature management.

While compound chocolate lacks tempered chocolate's superior snap and glossy appearance, it performs reliably for learning letter molding techniques. Many professionals use compound chocolate for practice runs before attempting designs with premium tempered couverture.

Step-by-Step Letter Molding Process

Systematic approach to chocolate letters ensures consistent professional results across all character production.

Preparing Letter Molds

Clean letter molds thoroughly with warm soapy water ensuring complete removal of any residues. Rinse completely and dry with lint-free cloth or allow air-drying inverted on clean towel. Any moisture causes chocolate to seize creating grainy texture and white spots ruining finished letter appearance.

Polish mold cavities with soft cotton cloth removing dust particles and fingerprints. Letter details like serifs, counters, and terminals require special attention; use small brushes accessing intricate areas scrapers can't reach. Inspect molds for damage particularly in delicate letter features like the crossbar in "H" or curves in "S" where stress concentrates.

Allow molds to reach room temperature approximately 65-70°F (18-21°C) before use. Cold molds cause chocolate to set too quickly creating thick edges and poor detail capture, while warm molds prevent proper crystallization. Temperature equilibration proves especially critical for letters containing fine typography details.

Creating Solid Letter Chocolates

Pour tempered chocolate into letter cavities until slightly overfilled for solid production. Tap mold firmly on counter 15-20 times releasing air bubbles trapped in letter details. Letter forms with enclosed spaces like "A," "B," "D," "O," and "P" particularly benefit from vigorous tapping ensuring complete filling without air pockets.

Use a scraper removing excess chocolate from mold surface, creating flat backing enabling letters to stand upright or adhere flat against surfaces. Scrape at slight angle ensuring clean removal without leaving chocolate buildup on mold edges.

Allow chocolate to crystallize completely before demolding. Room temperature setting requires 30-45 minutes for tempered chocolate, though refrigeration accelerates process to 15-20 minutes if production schedule demands. Chocolate develops satin finish and contracts slightly from cavity walls indicating readiness for demolding. Invert mold over clean parchment paper and tap gently; properly set letters release cleanly without forcing.

Making Hollow Letter Shells

Hollow letter construction reduces chocolate usage while creating impressive dimensional pieces. Pour chocolate into cavities then immediately invert mold allowing excess to drain back into bowl. Rotate mold during draining ensuring even coating across all letter surfaces including intricate interior details.

Use a soft scraper removing excess from mold surface while chocolate remains fluid. Place mold right-side up allowing first coat to crystallize until tacky but not fully hard, approximately 5-8 minutes. Apply second coating using identical method, building shell thickness to desired strength without excessive weight.

Two thin coats create stronger shells than single thick layer. Allow final coat to crystallize completely before demolding. Hollow letters work beautifully for large display pieces, cake toppers, or filled applications where substantial chocolate thickness would overwhelm other elements.

Creative Coloring and Decoration

Elevating chocolate letters from basic to extraordinary involves strategic decoration techniques adding visual impact and personalization.

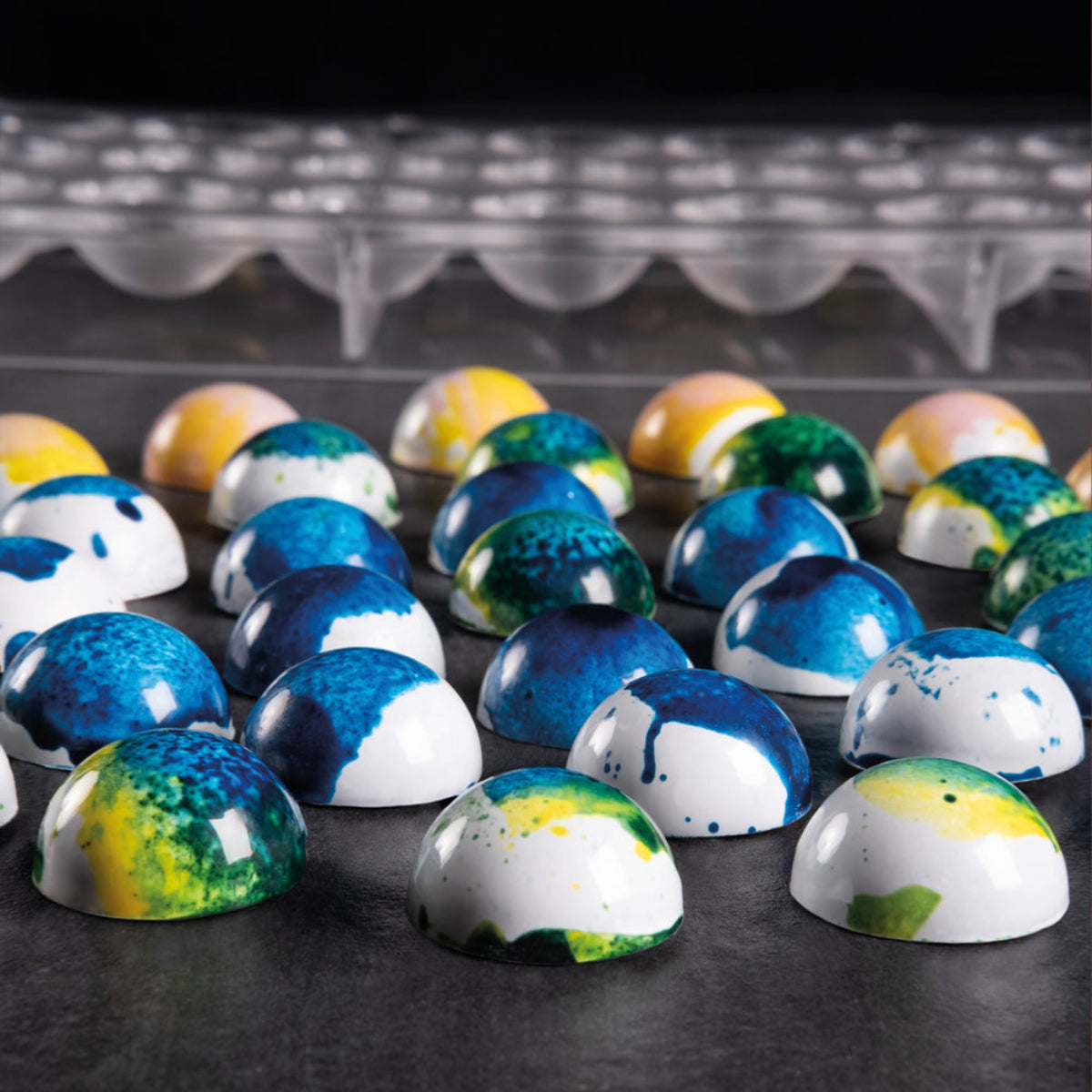

Pre-Coloring with Cocoa Butter

Painting molds before chocolate addition creates stunning colored letters without surface application. Warm cocoa butter colors to liquid consistency and paint directly into clean mold cavities.

For uniform letter coverage, professional spray equipment delivers exceptional results. Apply light coats allowing crystallization between layers building color intensity gradually.

Popular color combinations include red for Valentine's messages, gold for luxury branding, and blue for baby celebrations. School colors, corporate branding, or team logos translate beautifully into colored chocolate letters using this professional technique.

Adding Metallic and Shimmer Effects

Metallized finishes create premium chocolate letters perfect for upscale events and corporate gifts. Pearly Chocolate Grains Gold dusted onto set letter surfaces add luxury shimmer, while silver finishes provide sophisticated shine.

Apply metallic powders after demolding using soft brushes for subtle highlights or mix with neutral alcohol and spray using airbrush systems for complete coverage. Copper and bronze options offer warm metallic choices for autumn themes or rustic presentations.

Pearly grains in various colors pressed into partially set chocolate create textured accents highlighting letter features. These decorative elements elevate simple letters into premium confections suitable for high-end applications.

Surface Decoration Techniques

Enhance demolded letters through additional surface decoration. Drizzle contrasting chocolate over letters creating striped or marbled effects. Pipe small details like dots, lines, or flourishes using pastry bags fitted with fine tips. Our decorating combs and scrapers create textured patterns in chocolate before full crystallization.

Consider adding edible decorations like gold leaf, sprinkles, or sugar pearls. These embellishments should complement rather than obscure letter readability. Strategic placement emphasizing letter curves or terminals draws attention while maintaining legibility essential for personalized messaging.

Applications and Creative Uses

Chocolate letters suit diverse applications from celebration decorations to corporate branding opportunities.

Personalized Gifts and Messages

Individual letters spelling names, initials, or short messages create meaningful gifts. Box sets spelling "LOVE," "HAPPY BIRTHDAY," or recipient names offer personalized alternatives to generic chocolate boxes. Our display options showcase letter arrangements beautifully while protecting chocolate during presentation and transport.

Anniversary celebrations benefit from chocolate letters spelling significant dates or romantic messages. Wedding favors featuring couple initials or "MR & MRS" provide memorable keepsakes guests appreciate. Holiday letters spelling "NOEL," "JOY," or family names create festive decorations doubling as edible treats.

Cake and Dessert Decoration

Making chocolate letters for cake topping requires considering weight and attachment methods. Larger letters work well for sheet cakes with substantial surface area, while smaller letters suit standard rounds or cupcakes. Attach letters using small amount of melted chocolate, buttercream, or ganache creating secure bond without sliding.

Consider letter thickness when planning cake decoration; excessively thick letters add considerable weight potentially damaging delicate cake structures. Hollow letters provide dimensional impact without excessive weight for tiered cakes or elaborate designs.

Corporate and Event Branding

Businesses leverage chocolate letters for branded giveaways, event favors, and corporate gifts. Company initials or logos adapted to letter form create memorable promotional items. Trade show booths distribute chocolate letters spelling brand names generating positive associations while providing practical marketing tools.

Event planners incorporate custom chocolate letters into themed parties, fundraisers, and celebrations. Charity event letters spell cause names or honoree initials, auction items feature donor recognition, and conference swag bags include personalized chocolate messaging. These applications require volume production capabilities and consistent quality control ensuring professional brand representation.

Troubleshooting Letter-Specific Issues

Chocolate letters present unique challenges beyond general chocolate molding, requiring specialized solutions.

Broken Letter Features

Delicate letter components like serifs, terminals, and thin crossbars break easily during demolding or handling. Ensure complete chocolate crystallization before attempting removal; premature demolding causes breakage even with properly tempered chocolate. For particularly delicate features, consider reinforcing with additional chocolate layer or redesigning letters using sturdier fonts.

Temperature management affects brittleness; excessively cold chocolate becomes fragile while overly warm chocolate remains soft. Maintain proper working temperature throughout production using temperature monitoring equipment.

Air Pockets in Letter Details

Letter forms with enclosed spaces trap air more readily than simple shapes. The counters in "A," "B," "D," "O," "P," "Q," and "R" require special attention during filling. Use small brush or pick working chocolate into enclosed areas before tapping. Tap mold from multiple angles encouraging air to escape through various paths.

Chocolate viscosity significantly impacts air entrapment; thicker chocolate traps more air than properly fluid chocolate. Maintain correct working temperature and consider adjusting chocolate with small amounts of cocoa butter if viscosity proves problematic for detailed production.

Inconsistent Letter Thickness

Uneven chocolate distribution creates letters with thick sections and thin spots affecting both appearance and structural integrity. Pour chocolate deliberately into each cavity rather than quickly splashing across multiple letters. Use a spatula encouraging even distribution before tapping releases air.

For hollow letters, rotation speed and duration during draining determines thickness consistency. Develop standardized procedure timing rotations and drain periods ensuring uniform shell thickness across all production. Document successful techniques enabling consistent reproduction across batches.

Storage and Handling Best Practices

Proper storage preserves chocolate letter quality while careful handling prevents damage to delicate letter features.

Storage Conditions

Store finished chocolate letters in single layers separated by parchment paper within airtight containers. Maintain stable temperature 60-65°F (15-18°C) with humidity below 50% preventing bloom and softening. Letters with delicate features require extra care; avoid stacking or compressing during storage.

|

Storage Factor |

Recommendation |

Letter-Specific Consideration |

|

Temperature |

60-65°F (15-18°C) |

Prevents softening of thin features |

|

Humidity |

Below 50% |

Critical for white chocolate letters |

|

Layering |

Single layers preferred |

Protects delicate serifs and terminals |

|

Duration |

2-3 months (tempered) |

Quality window for gift sales |

Label containers with production dates and character inventories tracking available letters for custom message assembly. This organization streamlines order fulfillment for personalized products requiring specific character combinations.

Packaging and Transport

Transport chocolate letters carefully protecting delicate features from shock and pressure. Individual compartmentalized boxes prevent letters from contacting each other during shipping. For display purposes, secure letters to backing boards using small chocolate dots creating stable arrangements resisting movement.

Clear packaging allows visual appreciation without unwrapping while protecting creations from handling damage. Include care instructions explaining proper storage and consumption timeline ensuring customers enjoy optimal quality. Professional packaging elevates perceived value justifying premium pricing.

Scaling Letter Production

Moving from small-batch production to commercial operations requires systematic workflow and quality control implementation.

Production Planning

Analyze common letter usage frequency when planning inventory. Vowels and common consonants like T, N, S, R require larger quantities than less frequent letters like X, Z, Q. Complete alphabet sets enable balanced production addressing typical message demands.

Organize workspace efficiently with dedicated stations for tempering, molding, demolding, and decoration. This assembly-line approach maximizes productivity while maintaining quality standards. Professional chocolate melting equipment maintains consistent temperature eliminating repeated tempering between batches.

Quality Control Systems

Establish inspection criteria ensuring consistent quality. Check each letter for complete filling, clean edges, absence of air bubbles, and proper gloss. Reject pieces with visible defects for remelting rather than selling substandard products affecting brand reputation.

Document production variables including chocolate source, tempering methods, ambient conditions, and any issues encountered. This record keeping identifies patterns affecting success rates, allowing process refinement over time. Temperature and humidity logs prove invaluable when troubleshooting recurring production problems.

Equipment Investment

Quality equipment transforms production efficiency and consistency. Professional tempering machines eliminate manual variability, while specialized equipment enables coating applications. Professional cooling solutions maintain optimal crystallization temperatures regardless of ambient conditions. For more guidance, explore our article on how to choose the best chocolate tempering machine.

Consider educational resources from master chocolatiers providing advanced techniques and troubleshooting guidance. Professional training accelerates skill development for commercial operations.

Conclusion

Mastering chocolate letters with molds combines technical chocolate craftsmanship with typography awareness, producing personalized confections that communicate meaningful messages through edible medium. Success requires understanding proper mold selection, executing precise tempering techniques, and applying finishing methods that enhance rather than obscure letter legibility. Whether creating heartfelt personal gifts, decorating celebration cakes, or developing branded corporate products, these methods provide comprehensive foundation for chocolate letter excellence. Explore professional chocolate molds, premium fine chocolate varieties, and specialized decoration supplies at Zucchero Canada to craft chocolate letters that impress through both visual impact and exceptional quality.

References

Greweling, P. (2023). Chocolates and confections: Formula, theory, and technique for the artisan confectioner (3rd ed.). John Wiley & Sons.

KREA Swiss. (2024). Professional food equipment and spray systems for chocolate decoration. https://kreaswiss.com/food-equipment

National Confectioners Association. (2024). Chocolate molding standards and production best practices. NCA Technical Manual.

Pavoni Italia. (2024). Professional color collections for chocolate artistry. https://pavonitalia.com/en/collections/professional-collezioni-colori-e-materie-prime

Spagnuolo, P. (2023). Typography in confectionery: Design principles for edible lettering. Culinary Arts Review, 28(3), 112-125.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.