Fast delivery. Thank you very much!

Thank you very much!

This is the best flour that we have used. We do all of our cooking from scratch and are very impressed with the quality of this flour. We also appreciate the fact that we can buy it in larger than standard amounts as we use it up very quickly. So glad that we found this.

Thank you so much for taking the time to share your experience! We’re truly happy to hear that you’re enjoying the quality of the flour and that it meets your needs for scratch cooking. Offering larger formats for professionals and passionate home bakers is very important to us, so it’s great to know this makes a difference for you.

We sincerely appreciate your trust and are glad you found us. We look forward to continuing to support your baking and cooking projects!

— Zucchero Canada

Ordered flour (Order #2525) December 18th and now it is December 30th and the order has not arrived through Canpar Express. Not very express. Not sure maybe there was another option to pick a different delivery process?

Hi Thomas,

Thank you for your message. According to the tracking information, your order is scheduled to be delivered today, and we are continuing to monitor it until it is received.

At checkout, Regular Parcel was selected as the shipping option. For reference, delivery times with Canada Post’s regular service would typically be longer, especially during this season. That said, we completely understand how frustrating delays can be, and we truly appreciate your patience.

If possible, we would kindly ask that any product review focus on the quality of the flour itself, as shipping delays are related to the carrier and not the product. We would love to hear your feedback once you receive and use it.

Please let us know if there is anything else we can assist you with.

Thanks!

Sales Team

The beans we wanted were not available…. We’re having to get used to this flavour.

Hi Chuck,

Thank you for your feedback. We apologize that the beans you were looking for were not available. We understand that it can be disappointing when your preferred choice is not in stock. We hope that you will still enjoy the flavor of the beans you received. If you have any further concerns or questions, please don't hesitate to reach out to us. We are always happy to assist our customers. Thank you for choosing our product.

Best regards,

Customer Service Team, Zucchero Canada

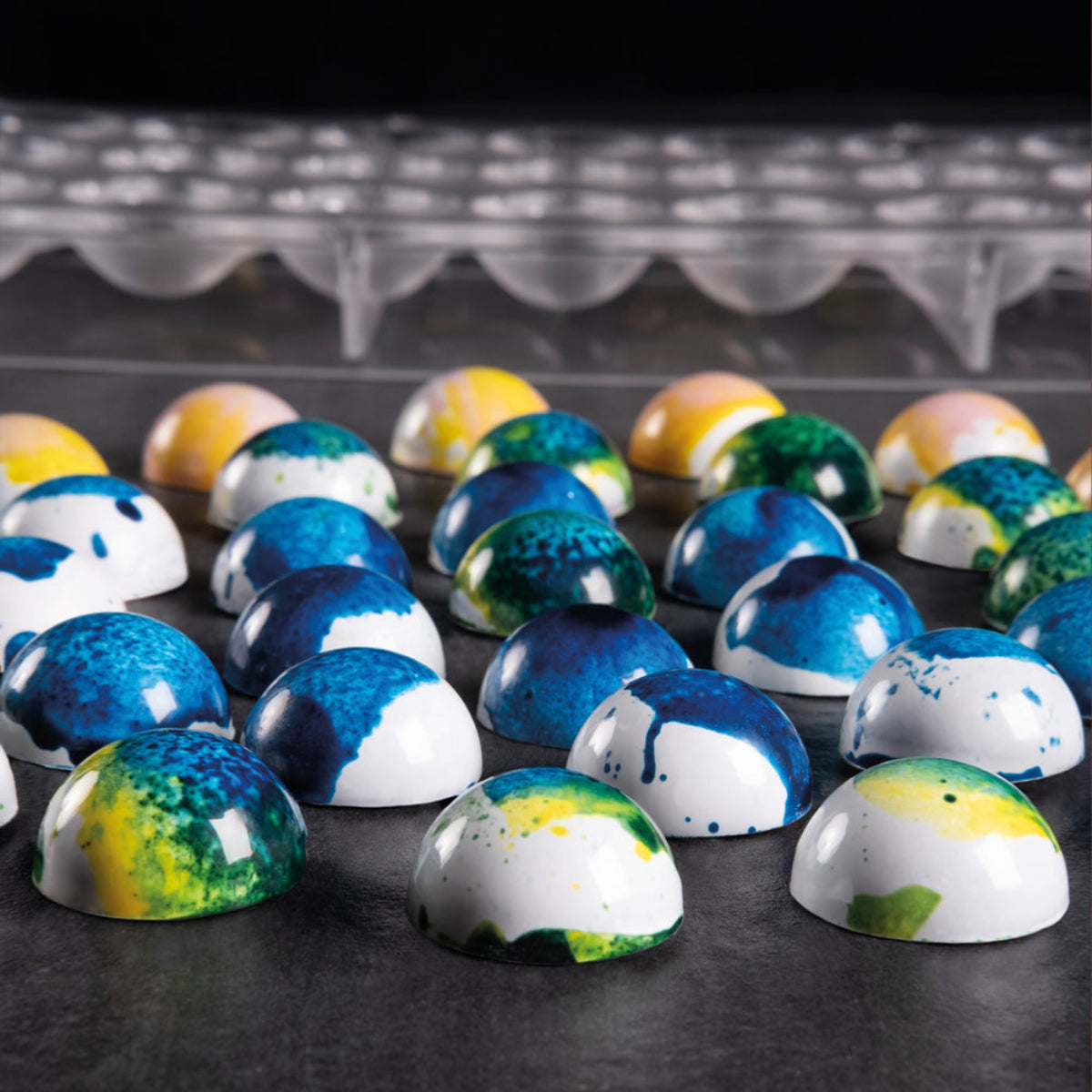

I purchased a 3.6L digital chocolate melter and although it took longer to an expected I did receive my purchase. Kati was fantastic and quick to respond to my inquiries. She updated me every step of the way, as well compensation for the unexpected wait time. I am happy that I choose Zucchero Canada, the customer service was top notch with a superb product quality. I will definitely order again sometime.

Dear Kristin,

Thank you so much for your kind words and for choosing our 'Digital Meltinchoc' Chocolate Melter 3.6 L! We are thrilled to hear that you had a positive experience with our customer service and that you are satisfied with the product's quality. We apologize for the longer wait time, but we are glad to know that Kati was able to assist you and provide updates along the way. We truly appreciate your support, and we look forward to serving you again in the future.

Best regards,

Zucchero Canada Team